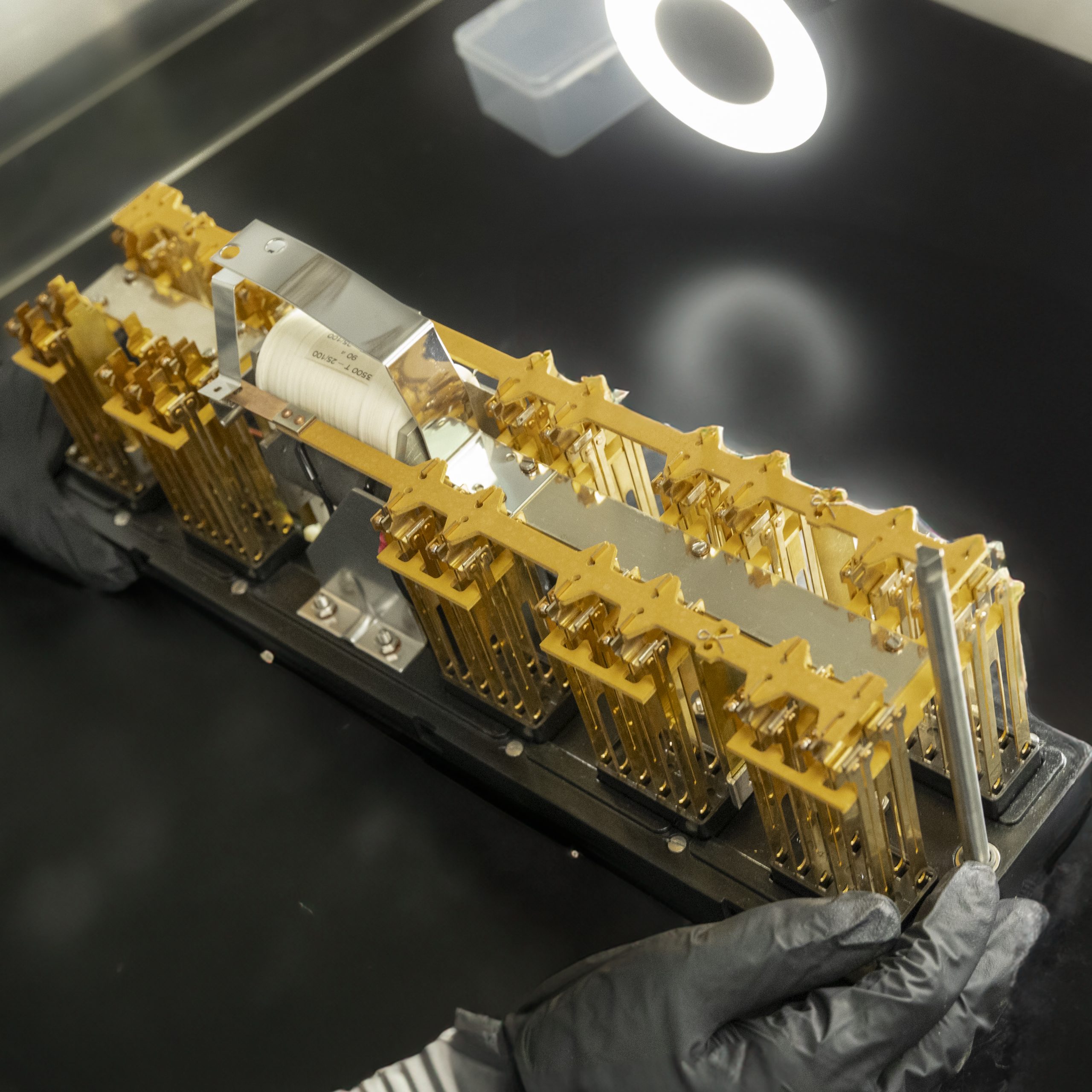

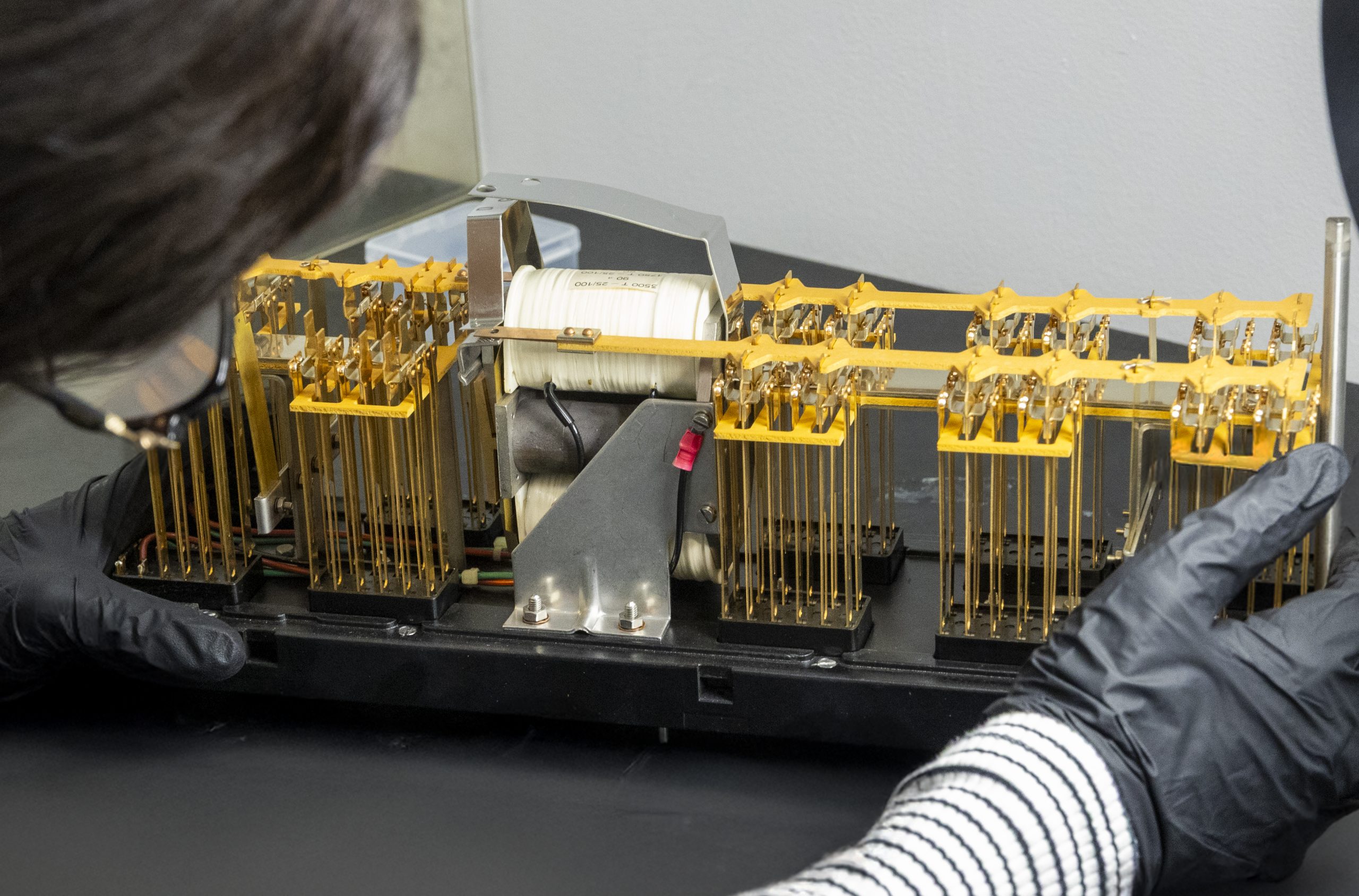

RELAYS INSPECTION

Visual Inspection

The inspection begins with a guided visual check, aiming to detect obvious defects such as wear, corrosion, mechanical deformation, or missing components.

LEIC provides a list of standard checks based on its extensive field experience, which clients can customize or expand according to their internal procedures. These checks are fully integrated into the NS1-Manager software, allowing for easy data entry and complete traceability within the automatically generated report.

Electrical Inspection

The test bench then performs automated measurements in compliance with railway standards (NF F70-030, NF F70-031, NF F70-032, etc.), including:

– Contact resistance

– Coil resistance

– Operating (or switching) time

– Switching currents

– Insulation resistance

– Special tests (break, locking, etc.)

The results are compared to defined thresholds, fully documented, timestamped, and digitally signed in a comprehensive report.

Implementation Modalities

LEIC can perform these inspections on-site in the client’s technical facilities or directly in their workshop, depending on operational constraints and workload.

These interventions may occur in various contexts:

– After relay relocation (corrective maintenance or infrastructure works)

– As part of scheduled periodic checks to maintain the fleet

– Following a detected failure during service

– Before recommissioning an installation

– In preparation for a rehabilitation campaign

Non-Conformity Management

In the event of a major non-conformity, LEIC immediately notifies the client so the relay can be isolated or replaced as quickly as possible.

For minor deviations, a specific monitoring plan can be implemented and integrated into a progressive rehabilitation campaign, helping to anticipate replacements while maintaining system availability.

Workshop-Based Inspection with Stock Rotation

LEIC also offers relay inspection services within its own workshops. This operating method is based on a stock rotation system, involving the use of a temporary buffer stock to replace relays sent for inspection.

This method offers several advantages:

– No operational downtime, thanks to replacement relays

– Grouped transport and simplified logistics

– Immediate rehabilitation in case of non-conformity, with no material return

– Time savings and reduced handling

– Increased reliability thanks to a stable and calibrated test environment

This setup is particularly well suited for:

– Annual preventive maintenance plans

– Progressive renewal operations of relay fleets

– Organizations wishing to outsource inspection and repair operations