REHABILITATION OF RELAYS

Extending Their Lifespan, Preserving Our Future

Rehabilitating Relays: A Sustainable, Controlled, and Optimized Solution

At LEIC, we have made the strategic decision to design our own mechanical and software tools for relay rehabilitation. This approach allows us to guarantee optimal precision, significantly reduce intervention times, and thereby control costs for our clients.

Our automated test benches, integrated analysis software, and centralized database ensure reliable, repeatable adjustments that fully comply with current standards. Each relay is processed following a structured protocol, managed by a computerized system that guarantees full traceability of every step.

Our approach is fully aligned with a Corporate Social Responsibility (CSR) philosophy:

– Less waste, more reuse: by extending equipment lifespan, we help reduce the sector’s ecological footprint.

– Circular economy: rehabilitation is a sustainable alternative to systematic replacement.

LEIC combines cutting-edge technology, strict compliance with standards, and environmental commitment to deliver efficient and responsible relay rehabilitation.

Our Relay Rehabilitation Process

The rehabilitation process implemented by LEIC is based on rigorous organization, custom-developed tools, and a computerized tracking system that ensures the reliability, traceability, and cost-efficiency of every intervention.

1. Reception and Registration

Relays are received, then undergo visual and electrical inspection.

Each relay is identified and registered in our digital system with its serial number, origin, and history.

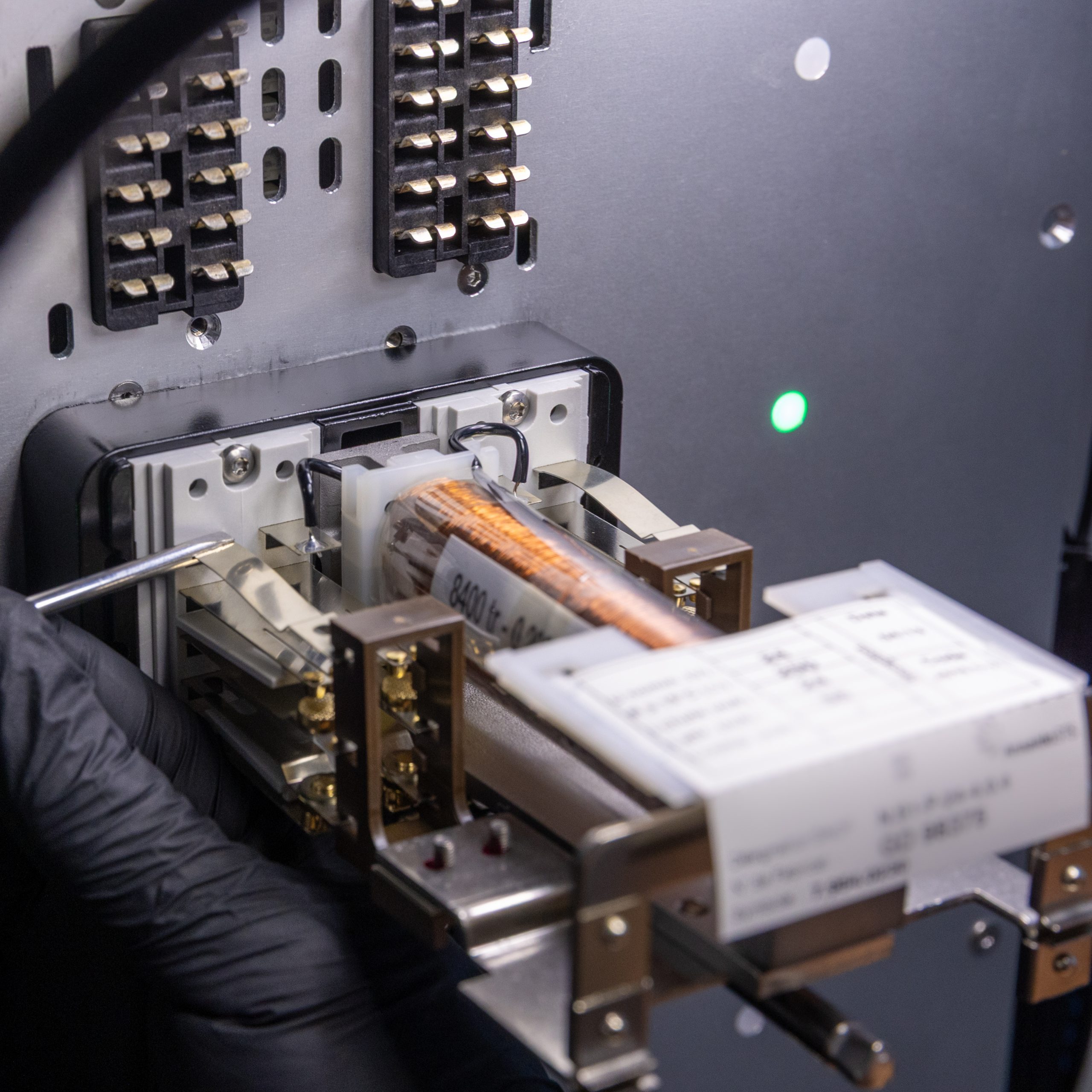

2. Multi-Station Rehabilitation Line

The relay goes through a structured line with several successive workstations:

– Opening and internal inspection

– Complete cleaning in a dedicated area to avoid contamination (housing, contacts, coils, etc.)

– Mechanical adjustments via automated benches controlled by optimization software

– Full electrical testing: resistance, insulation, response time, etc.

All tests are performed using automated benches developed by LEIC, connected to a centralized database that integrates the applicable standards for each type of relay.

3. Finalization and Traceability

Once the results are validated, the relay is reassembled, sealed, labeled, and tested one final time.

A complete report is generated (visual, electrical, mechanical), incorporating standards, procedures, and results.